Lobby Space Solution

Elevating Homes Through Majestic Lobbies

ONE-STOP VILLA SOLUTIONS

Luxury Lobby Solution

We are committed to providing one-stop modern or classic luxury hotel and villa lobby decoration solutions. Through cleverly designed space layouts, high-quality materials and touches, as well as clever lighting, bespoke artwork, we create an impressive and luxurious environment that enhances the quality of your hotel or residence. You can tell us your idea and our team will give you a solution.

WE OFFER

Luxury Lobby Design Styles

Explore our diverse lobby styles! Modern luxury blends comfort, classical court style exudes elegance and history, contemporary design showcases sleek efficiency, and French style brings romance and refinement.

Modern Luxury Lobby Design

The entry door serves as a pivotal facade in luxury home design, ensuring both security and privacy while defining the overall style and welcoming guests.

Modern Minimalist Lobby Design

The entry door serves as a pivotal facade in luxury home design, ensuring both security and privacy while defining the overall style and welcoming guests.

Classic Palace Lobby Design

The entry door serves as a pivotal facade in luxury home design, ensuring both security and privacy while defining the overall style and welcoming guests.

French Lobby Design

The entry door serves as a pivotal facade in luxury home design, ensuring both security and privacy while defining the overall style and welcoming guests.

EXPERIENCE SEAMLESS CUSTOM DELIVERIES

Luxury Lobby Design Elements

The exquisite beauty of the mansion’s lobby comes from carefully selected elements like dazzling chandeliers, elegant sculptures, refined furniture, and exquisite carpets. These elements complement each other, creating a luxurious and comfortable ambiance.

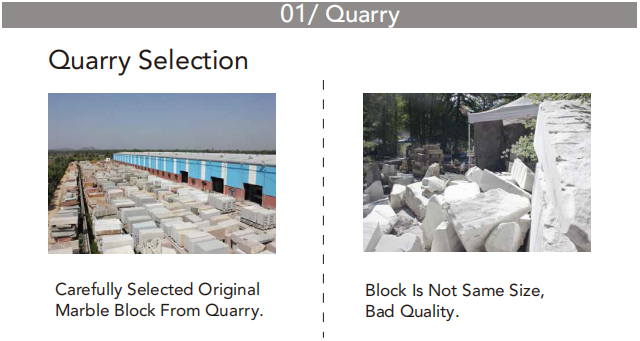

Marble Flooring

Wall Panel

Crystal Chandelier

Soft Decoration

Wooden Door

Furniture

Spiral staircase

FROM PROJECT DESIGN TO COMPLETION

Factors Impacting Entrance Costs

Entrance Size & Layout Complexity

The size, shape, and complexity of the entrance hall directly impact construction and decoration costs. Larger or irregularly shaped spaces may require more materials and labor to complete the design.

Material Selection

Choosing high-end or custom materials Choices such as flooring materials (like marble or hardwood), wall finishes (such as wallpaper, paint, or stone veneer), door materials, and lighting fixtures significantly influence costs. Opting for high-end materials or custom options typically increases the overall quotation.

Decor and Accessories

Costs for furniture, decor items, artwork, and other decorative elements are included in the total quotation based on their selection and installation requirements.

Technical Requirement

Specialized technical treatments or custom designs, such as unique architectural structures, complex lighting systems, or bespoke furniture, can escalate project complexity and costs.

jadwah-Let stone create its own legend.

Most people think stone is lifeless and rigid, but eachpiece of stone has it’s own character. The combination of stone and architecture will create many possibilities Witness more works about stone and architectural art !

FAQ

FAQs of Luxury House Entrance Hall

Discover lobby design FAQs with quick answers on costs, process, materials, and more. Clear guidance for all your questions.

Ground unevenness is a common problem in paving marble, so it is generally necessary to have mirror polishing treatment after paving

PFM exports all kinds of stone to the world,and recent years we undertaken a variety of projects which valued in the millions each of which is to abroad. With a professional design team and experienced construction team, we are capable to provide you full one-stop services and turnkey solutions.

The Cause Of Stone Water Spots

We represented as a subcontractor of a famous contracting company on year 2018, in Doha Qatar. Our cooperation was for a public project; including a mosque and four office buildings. We shipped more than 40 containers to the site within 4 months; catching the tight deadline. From the drawing confirmation to the cutting size, we perfectly achieved every target.

Other than material supply. We also provided labor for the installation. We brought the best craftsmen to install the marble tiles. Earning a great reputation for our quality materials, technical knowhow, and hard working spirit.

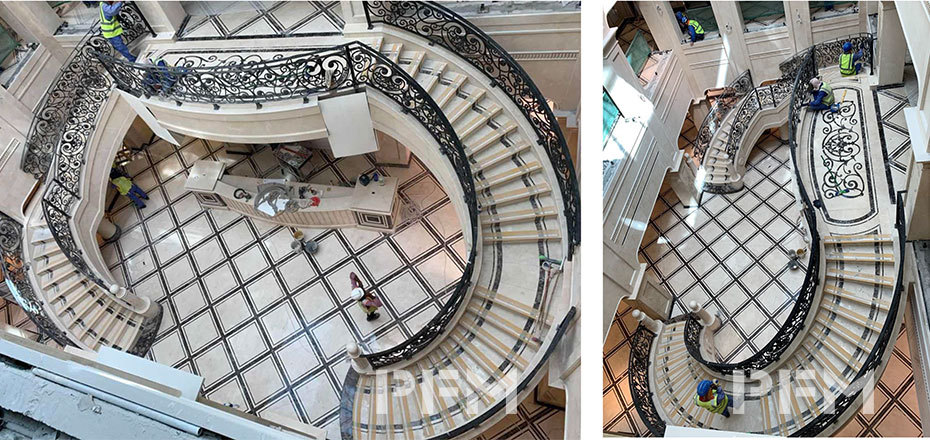

The Key Point of Curved Staircase

A well-designed curved staircase offers much more than its functional purpose. In fact, a staircase is an integral facet of design, a focal point, and often the first piece of furniture seen by visitors. Beautiful and complex, curved stairs are considered the pinnacle of stair craftsmanship.

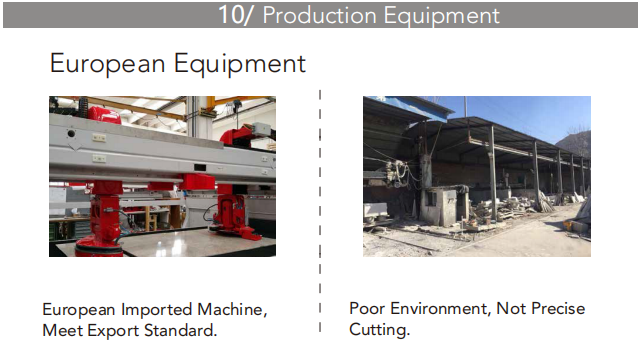

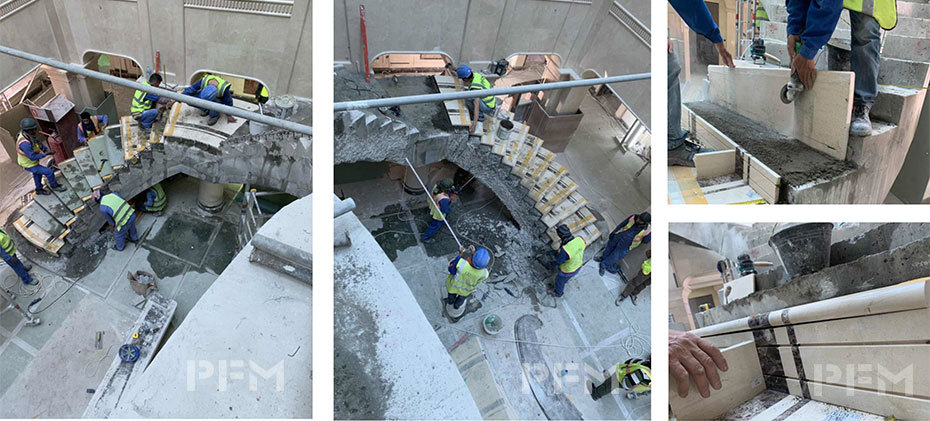

1.Technique Difficulty

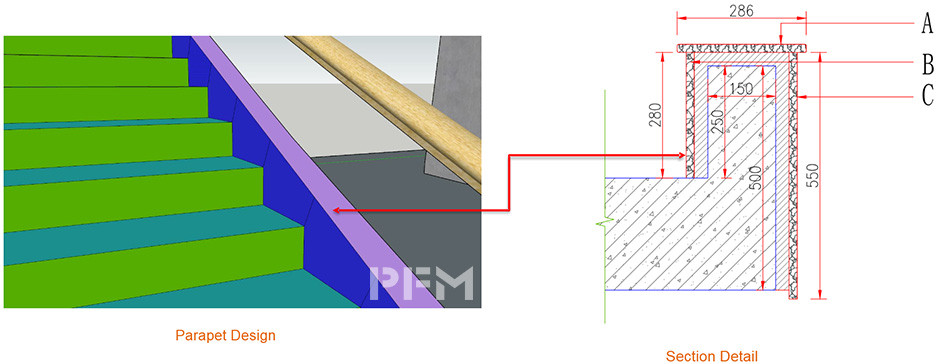

The technical difficulty of the stone curved/ arched staircase is indeed the process of the cover plate, base plate and handrail which neither the software nor the experienced master can make it accurately.

2.Process Difficulty

The maximum they can do is to draw the length of the inner/outer arc as well as the altitude. Before processing, it still need to be adjusted ceaselessly according to the computer wire cut machine and rotary platform machine.

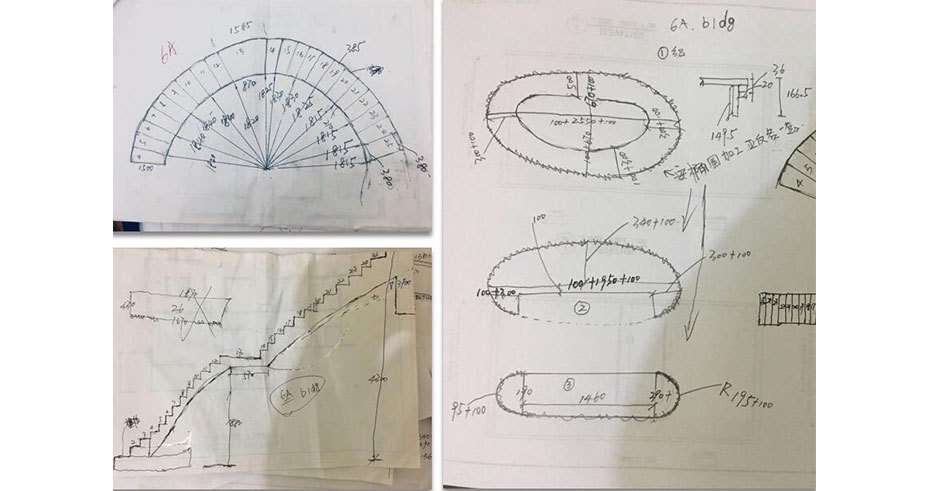

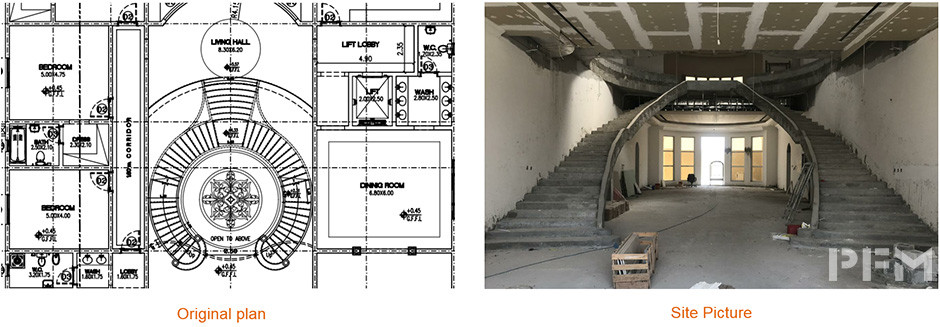

Step 1: Measurement data on site

Step 2: 3D Design Based on Requirement

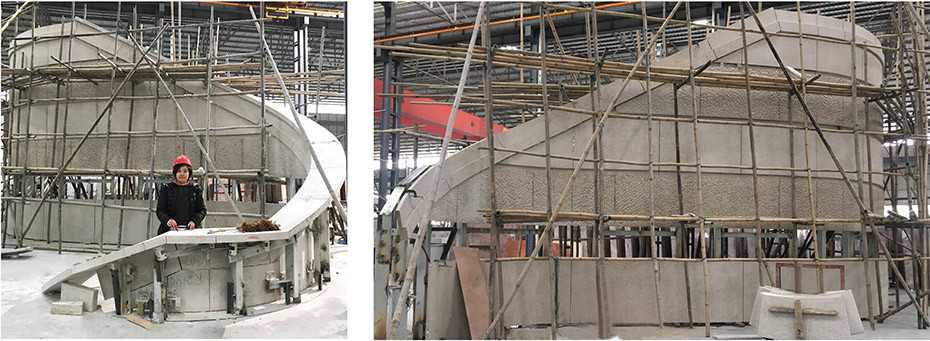

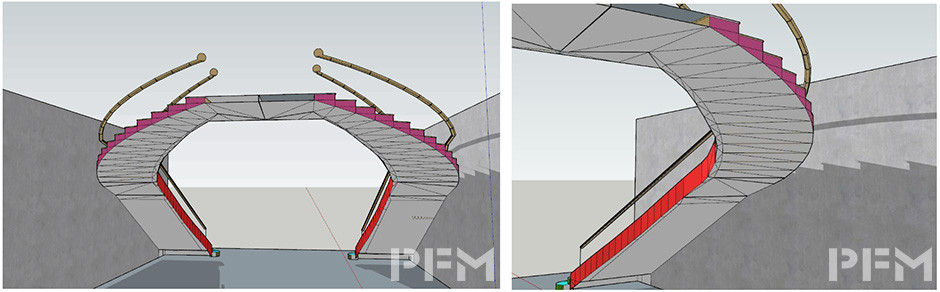

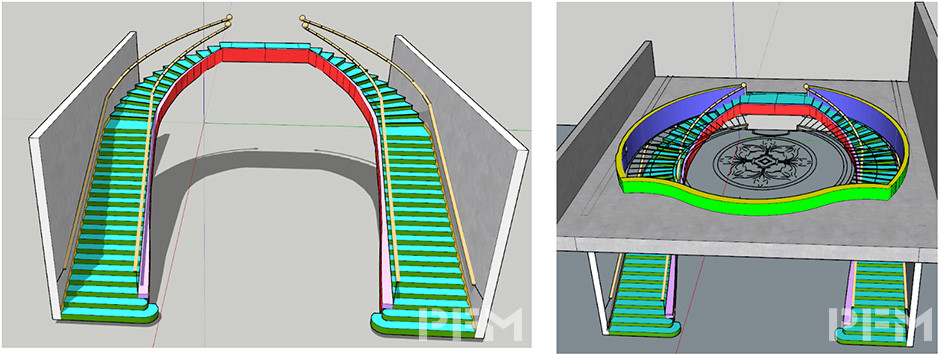

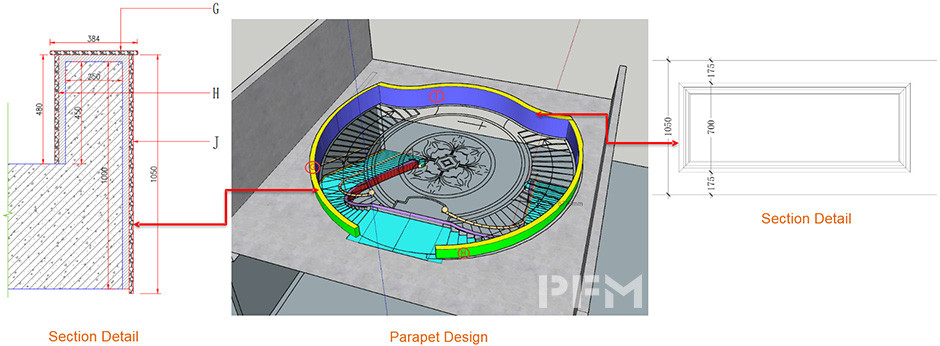

Qatar Curved Staircase Design

The successful production of the spiral staircase requires a scientific and accurate design, precise processing technology and a professional construction team. PFM made it into real.

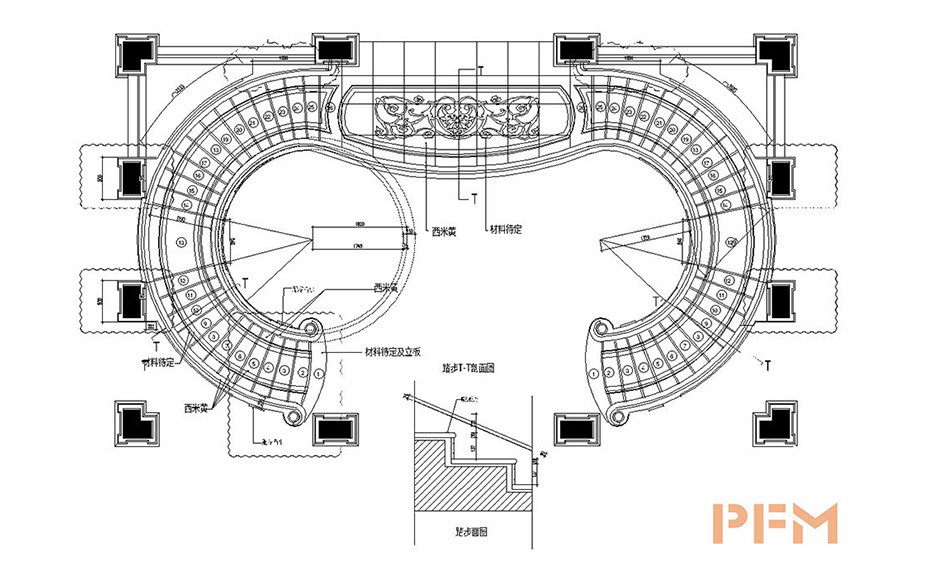

Step 3: CAD Plan & Section Drawing

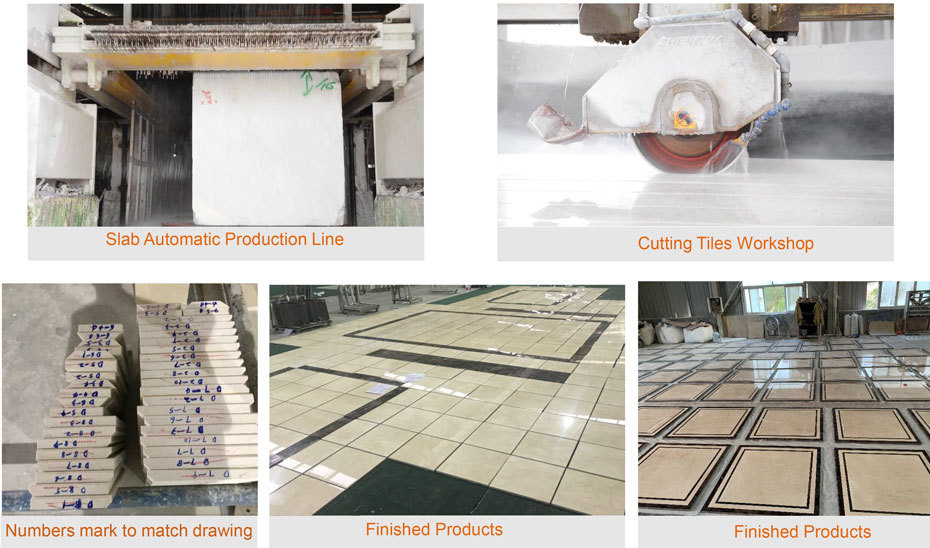

Step 4: Production Process

Step 5: Pre-assembling Staircase Frame

Step 6: Setting Up Metal Structure For Pre-assembling

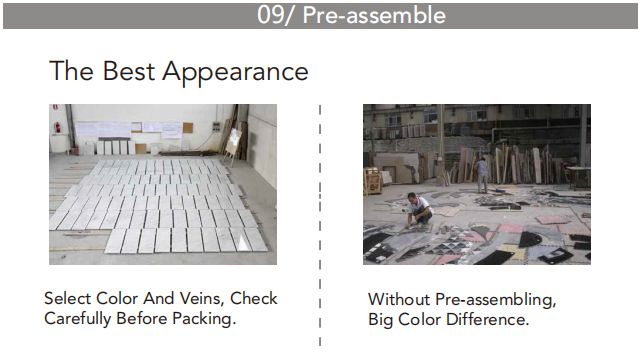

Step 7 : Pre-assemble Stair Tiles In Factory

Step 8: Curved Staircase Site

Step 9: During Installation By PFM Team

Step 10: Installation Completed

About PFM

Promising Flooring Material ltd. is one of the most successful, and rapidly expanding construction organizations in the east Asian region. Established in 2008, we offer the industry’s most comprehensive range of construction materials. We are a one of a kind, turn-key, interior and contracting solution provider.

Our aim is to continue to grow, by taking on projects that more than demonstrate what we are capable of. Surpassing expectations, and continuing to enhance the lives of our people.

We have a 900m2 aesthetic showroom with our latest products and designs on display. Our showroom presents a unique and valuable experience to customers.

To achieve our goals, we continue to innovate by embracing leading-edge technology, and constantly monitoring and enhancing the way we work.

Loading Details Of Stone Product

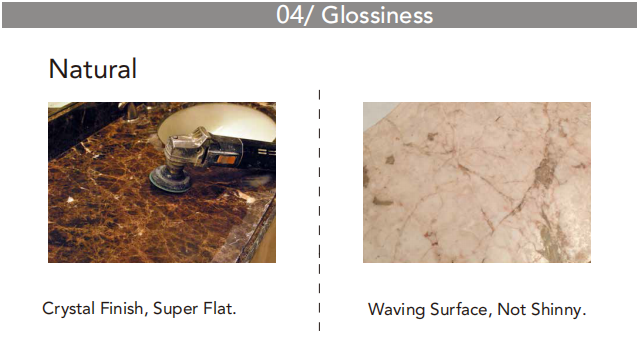

When we talking about MARBLE stone care with people, We always pay particular attention to two key words, “crystal treatment” and “mirror treatment”. Some people usually confuse with them, but for a professional marble stone supplier, these words need to be distinguished.

Let see the differences between the marble crystal face and mirror face.

First of all, , we can understand the difference in literally.

Crystal: The crystal is grown from the liquid or gas phase.

Mirror: It is an instrument which used for reflection.

From the professional perspective, there are substantial differences between crystal treatment and mirror treatment.

Crystal Treatment: It is a chemical reaction. Because of the chemical and physical reaction, the stone surface is formed a hard and dense crystal layer. So that the stone is not easily damaged. It can also be understood as crystallization. After the hot saturated solution cooling, the solution will be crystallized. For example, the marble calcification, the granite silicification and etc.

Mirror Treatment: It is a general term for all stone effects. Generally, the mirror surface is just by waxing.

Key Points Of Marble Crystal Finish Treatment

As high-grade natural stone flooring decorative materials, its structural components are more complex, it needs to carry out the necessary crystallization maintenance on a regular basis to ensure the decorative effect, to avoid the occurrence of cracks, surface peeling, loss of light, pollution, etc., and to extend the use of stone. Life expectancy, otherwise the decorative effect of the stone will be greatly reduced, and the stone will have a series of symptoms. Stone surface treatment is equivalent to the beauty restoration of stone. After hard treatment of the stone surface, the stone forms a hard crystal layer on the surface. The crystal layer not only improves the brightness of the stone, but also effectively protects the stone from abrasion and pollution.

A.National quality standard of floor crystal treatment

1. The stone surface is clean and tidy, the protection is intact and there is no damage.

2. The overall stone surface are delicate, oily, bright, Crystal clear.

3. The overall stone surface meter test average brightness of marble above 80 degrees, granite, quartz and nano stone more than 75 degrees.

4. The overall stone surface shows the sucker slip effect.

5. The overall stone surface exhibits a lotus effect and waterproof.

B.What is the general maintenance period of crystal treatment?

1. Because of the small flow of people, generally once a quarter is appropriate for the villa.

2. The entrances and exits of hotels and commercial buildings are twice a week.

3. The hotel, commercial building, elevator hall and other public areas are once a week.

Can you send workers to the site to measure the size? How to charge?

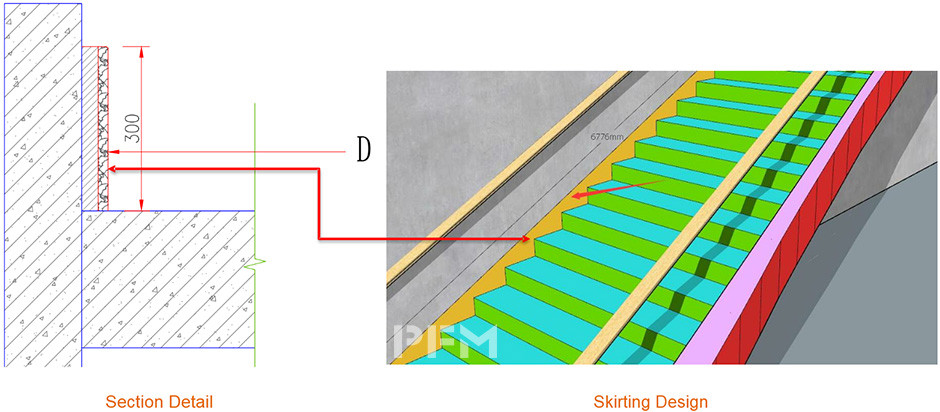

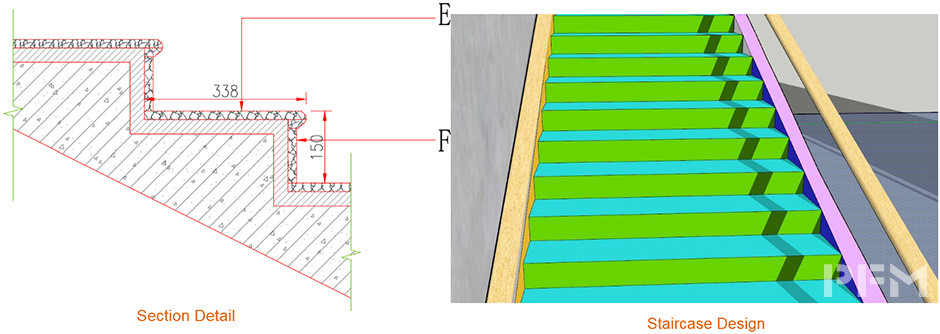

In order to explain more clearly how to make the marble stair based on original concrete structure, we make a 3D model of finished stair and provide sectional drawing of every part. Even personal house owner will understand how we will do the work with this proposal.

Design Reference from Client

Current Situation

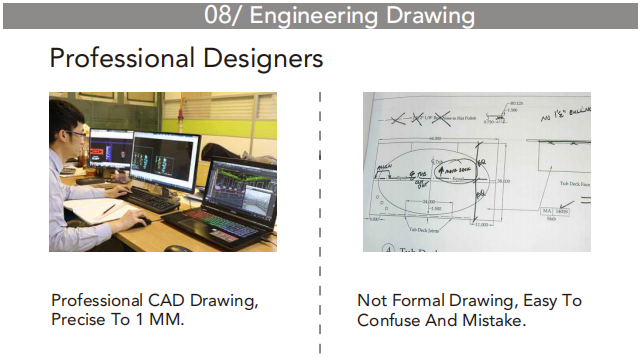

1.There is differnce between CAD and real site

2.We don’t have elevation drawing of the stair

–Thr crrent plan is not able to be used for quoting and producing

PFM Proposal Design

Above all,we customize a feasible proposal according to experience

Modeling Process

Staircase Structure-Part 01

Staircase Structure-Part 02

Staircase Structure-Part 03

Staircase Structure-Part 04

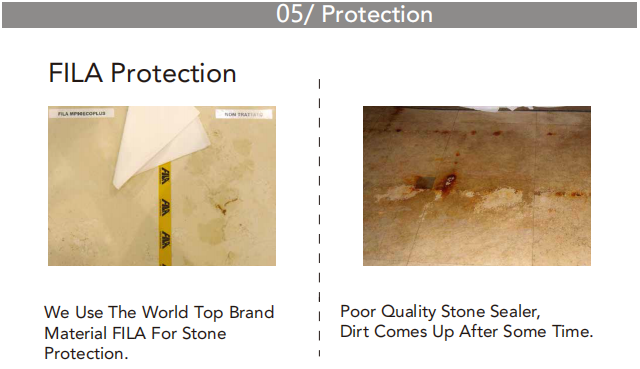

The traditional stone wetting installation is simple, easy to operate and low in cost. It is still widely used in stone installation projects. Therefore, it also brings a lot of stone disease after installation, the most remarkable phenomenon is stone water spots (stains) after drying for a long time. This question is plaguing many owners, construction units and stone suppliers.

We will be analyzed the cause of the water spots (stains) we have encountered in our work.

Firstly, different stone varieties. The stone that does not dry with water spots (stains) is mostly light-colored stones, and most of the granite stones. It is characterized by medium-acid magmatic rocks, high degree of crystallization, abundant micro-cracks between crystals, high water absorption, and high content of various metal minerals. Based on these characteristics, when we do the wetting installation, it is easy to chemically react with the metal minerals in the stone, and result in water crystals. Under normal conditions, it is difficult to evaporate and dry, as a result the stone has a long-term appearance of flooding.

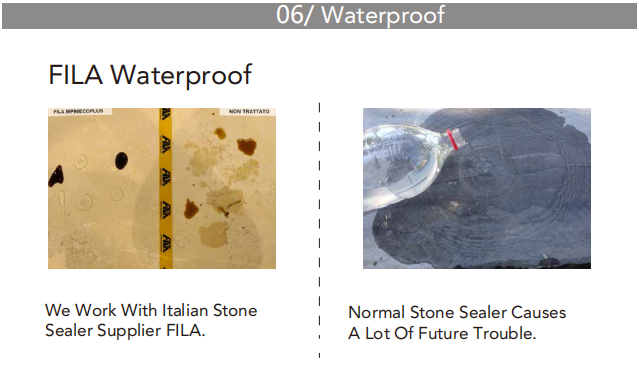

Secondary, the use of protective agents or varieties is not properly selected. There are many varieties of protective agents in the market, and different protective agents should be used for different stone materials, different parts of use, and different paving methods. This is often overlooked. More important is the fair choice of construction methods and usage. It is often found that even we used the same stone, same cement and sand, but the wall cladding and flooring still appear water spots (stains). This situation is basically the result of using a stone protective agents without actually operating requirements.

Thirdly, the choice of cement, sand and water consumption during stone paving also have a great influence on water spots and yellowing of stone. In the construction, the alkali content, manganese content, iron content, sand soil content (including impurities) and water should be strictly controlled. Otherwise, the stone will be contaminated by different procedures.

Loading Details Of Stone Product

The stone product are extremely fragile during the handling and unloading process. If it is accidentally damaged, the loss will be serious. So let us share something during the stone handling process and how to avoid unnecessary dangers.

Precautionary and prepared.

In order to be safe and free from loss, it can be prepared according to different conditions, product size, quality, distance, and different modes of transportation.

▶ If the large-size big slab, we suggest to use the hard wood for firmness.

▶ If the small slab, can be bundled with wooden slats and shovel.

▶ Specialty products and handicrafts should be packed in cartons and wooden boxes to protect sharp corners.

▶ It is strictly forbidden to pack the white and easily contaminated products with colored plastic and straw rope.

▶ The package should be secure and easy to load and unload.

▶ You need to write the box number and attached the packing list on the package.

▶ Pack with plastic film to prevent rain.

▶ The surface of the working piece should be foamed, and the bottom of the package should be filled with two crossbars for loading and unloading.

Key Points Of marble Crystal finish Treatment

1. Light-colored marble (Ariston White, Volakas, Calacatta, Arabescato, Sivec White, etc.) can not use the acidity chemical potions for the surface treatment. Light-colored stone has the high iron content, which is likely to cause yellowish surface after reaction with acidity potion.

2. The crumbly stone can not use the crystalline material which contains the resin material, otherwise, the resin wax will block the surface pores, It is not conducive to stone ventilation, and easily result the stone re-alkali, yellowing and other diseases.

3 The Tropical Brown marble, Dreamy Hainan, French Portoro and other materials which are unevenly and distributed material. These stone must be double crystallized. Otherwise, the stone surface is smooth with touching, but uneven in visual sense after the treatment.

4. The soft stone (White Sand Limestone, Moca Cream Limestone, etc.) must be treated with pores shrinking water before treatment, and then double crystallization, otherwise it will show astigmatism.

5 Granite and crystallized nano stone can not be polished with steel wool. Otherwise, the powder of steel wool will be sucked into the pores of the stone surface to be yellowing.

6 Dark granite must be retouching before crystallization treatment. Otherwise, when the crystal treatment finished, the stone surface will be dull, dry and whitish of the stone surface.

Yes we can send our engineer to come to job site to do measurement.

And Your company should pay for tickets,visa, and accommodation.

COMPLETED 105 PROJECTS IN 117 COUNTRIES AND REGIONS

Discover Our Projects

HOTEL

Le Chateau Palace

PALACE

Luxury Palace Project

VILLA

Luxurious Modern villa Project

SERVE

Support Service

Design Service

Professional Design, Experienced Team, Worry-Free Service!

Install Service

Professional Design, Experienced Team, Worry-Free Service!

Consultation Service

Professional Design, Experienced Team, Worry-Free Service!

Sample Policy

Professional Design, Experienced Team, Worry-Free Service!